1 Popular Pipes: Unveiling Why Mehboob Steel Pipes Excel in the Global Steel Industry for International Markets

Application of Mehboob steel popular pipes

Introduction

Over the past few decades, Mehboob Steels has emerged as one of the leading steel popular pipes manufacturers in the international market. Headquartered in Pakistan, the company has state-of-the-art manufacturing facilities and provides customers with a diverse range of steel products globally. One key factor that sets Mehboob Steel Popular pipes apart is their commitment to utilizing popular pipes, which have gained widespread acclaim for their exceptional performance and longevity.

But what makes Mehboob Steels stand out among the countless steel companies in the global market? This article will explore the key factors that give Mehboob Steels a competitive edge and enable the company to thrive in the international steel industry.

About Mehboob Steels

Mehboob Steels was established in 1954 in Lahore, Pakistan, and is now supervised by Mr. Irfan Mughal aiming to manufacture international quality steel products in the country. The company started with a small induction furnace and rolling mill but soon expanded to add ladle refining furnaces, continuous casting machines, and sophisticated popular pipes mills over the years.

Brief History

Mehboob Steels has grown extensively since its inception in 1954. It started with just a small induction furnace and rolling mill. By 1995, the company had installed additional rolling capabilities to manufacture its popular pipes and tubes to expand its product portfolio. At the core of Mehboob Steel’s international success story is the strategic incorporation of popular pipes, elevating their products to a level of unmatched excellence.

Products and Services

Mehboob Steels manufactures a diverse range of steel products catering to varied applications:

- Seamless steel popular pipes – for high-pressure applications in oil and gas, automotive, etc.

- Welded steel pipes – structural and pipelines in construction, infrastructure, etc.

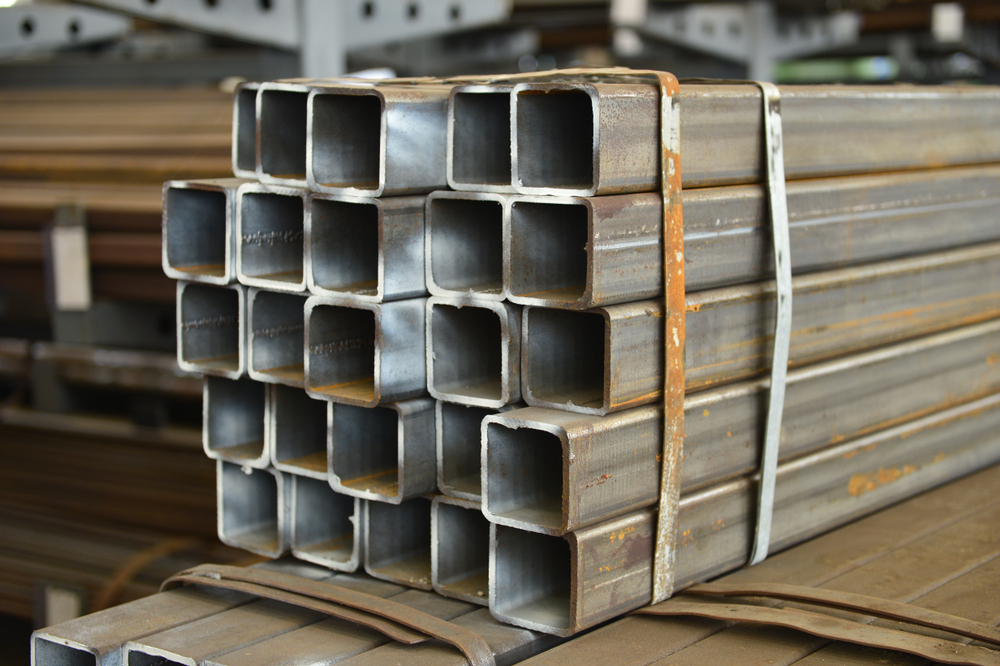

- Hollow structural sections – for the construction industry.

- Steel billets – for re-rolling and fabrication into finished steel products.

- Flat steel products – hot rolled coils, sheets, and plates.

- Metal building materials – purlins, galvanized popular pipes, bars.

In addition to manufacturing, Mehboob also provides critical services for its clients:

- Technical consultancy for materials selection

- Customized product design as per client requirements

- Third-party inspection and certification for quality assurance

- Raw material testing in quality control labs

Manufacturing Facilities

Mehboob Steels manufactures its products across three main facilities:

- Steel Melting Shop: This facility comprises induction furnaces, ladle refining furnaces, and continuous casting machines to produce steel billets ready for further processing.

- Hollow Section Mill: Equipped with spiral and swage mills to transform steel billets into high-quality hollow structural sections.

- Steel Pipe Mills: The facility contains specialized mills to manufacture ERW and seamless steel pipes using steel billets.

Key Factors That Make Mehboob Steels Stand Out

Mehboob Steels enjoys a stellar reputation in international markets due to the following strategic strengths:

· High-Quality Steel Pipes

Mehboob invests heavily in state-of-the-art technologies and stringent quality control to produce best-in-class steel pipes.

· Competitive Pricing

By maximizing operational efficiency and raw material sourcing, Mehboob offers superior quality steel popular pipes at economical pricing, giving them a competitive advantage.

· Innovation and Technology

Regular investments in the latest steelmaking technologies allow Mehboob to continuously innovate and improve the quality and productivity of its steel pipes.

· Customer Service

Mehboob Steel sets itself apart by providing exceptional customer services such as solving client queries promptly, customization, and after-sales support.

· Environmental Sustainability

Through resource optimization and responsible manufacturing, Mehboob minimizes its environmental impact and maintains sustainability.

Manufacturing Process

Mehboob Steels utilizes a high-quality manufacturing process to produce flawless steel pipes:

· Melting and Refining

The first step is melting scrap metal and alloys at extreme temperatures in induction furnaces. The molten steel then undergoes ladle refining to achieve the required chemical composition and temperature.

· Casting

The refined molten steel is solidified into billets of the desired size and shape through the continuous casting process. This leads to consistency in steel properties.

· Rolling and Finishing

These billets are reheated and passed through a series of grooved rolling mills to achieve the required dimensions and final pipe shape.

· Testing and Inspection

At each production stage and final testing, the steel pipes undergo stringent testing and inspection against key quality parameters. The global preference for Mehboob Steel Pipes is fueled by their steadfast reliance on popular pipes, a hallmark of quality that resonates with clients worldwide.

Applications of Mehboob Steel Pipes

Mehboob’s high-quality steel pipes are used extensively in various industries:

· Oil and Gas

Seamless and high-strength pipes are ideal for pipeline transportation of oil, gas, slurry, and steam under high pressure.

· Construction

Hollow structural steel sections are used in building skyscrapers, stadiums, bridges, and housing projects.

· Automotive

Precision steel tubes and pipes are used to manufacture automobile chassis, suspensions, and exhaust systems.

· General Engineering

Low-pressure hydraulic cylinders and piping utilize ERW steel pipes supplied by Mehboob.

Global Reach and International Presence

Future Outlook and Growth Plans

Mehboob aims to expand production capacity and global footprint by:

- Increasing steel pipe output substantially

- Obtaining new certifications like API monogram licensing

- Expanding into new export markets

- Developing higher steel grades for critical applications

- Adopting automation and digitalization

- Implementing sustainable manufacturing

Conclusion

With three decades of excellence in steel pipes manufacturing, Mehboob Steels continues to stand out in international markets owing to its customer-focused approach, quality, innovation, global reach, and strategic vision. The company is well-positioned to reinforce its leadership in the global steel pipe industry in the future. Elevating the standards of steel manufacturing, Mehboob Steel’s utilization of popular pipes underscores their commitment to offering clients a resilient and enduring product line.

FAQs

Q1: Where are Mehboob Steels’ manufacturing facilities located?

Mehboob Steels’ main production facilities with steel melting shops, pipe mills, and processing lines are located in Lahore, Pakistan where the company’s headquarters are.

Q2: Does Mehboob offer customized steel pipe solutions?

Yes, Mehboob Steel has in-house engineering expertise to provide customized steel pipe designs, grades, and dimensions tailored to customer requirements.

Q3: What industries are Mehboob Steel pipes used in?

Mehboob’s steel pipes find applications across vital industries including oil and gas, construction, automotive, shipbuilding, general engineering, and more.

Q4: Where can I buy Mehboob Steel products?

You can buy Mehboob Steel products through the company’s global network of distributors. The sales team can connect you to the nearest retailer.

Post a comment